Business Overview

One of the key technologies for realizing carbon neutrality involves next-generation batteries, nano-scale functional particles with various functions, the widespread adoption of 5G and 6G communication systems and environmentally friendly vehicles, passive components such as MLCCs that require ultra-miniaturization and high reliability due to advances in advanced driver-assistance systems (ADAS), high-quality healthcare enabled by digital transformation (DX), and medical devices that are becoming increasingly AI-driven and digitalized.

There are high expectations for our coating technologies in every field of society.

Liquid Phase Technologies

Liquid Phase Technologies

Propose best practices for materials, equipment, and processes

We provide process technologies, equipment, jigs, and contract services related to the forming of next-generation dielectric sheets, internal electrode processes, and external electrode coating (for both two-terminal and multi-terminal types) for passive components such as MLCCs, MLCIs, varistors, and thermistors. Our patented technologies and unique process solutions—supporting products as small as 0201mm—are designed to meet the diverse needs of our customers.

Gas Phase Technologies

Gas Phase Technologies

Low-temperature plasma-enhanced thin-film deposition as our core gas-phase technology, offering optimal deposition solutions for powders and devices

Our technologies enable the precise deposition of organic and inorganic materials (metals, compounds, oxides, nitrides) in thicknesses ranging from 1 nm to 1 µm onto complex surface shapes of various powders, such as battery and magnetic materials, as well as onto advanced devices. Additionally, they can be applied to the deposition of gas barrier films, corrosion-resistant films, conductive films, and insulating films.

AI × Robotics Technology

AI × Robotics Technology

From “Automation” to “Autonomy” Driven by AI Technology. We support inovations in new material discovery and process optimization by combining liquid-phase and gas-phase technologies with AI.

Robots autonomously evaluate material properties, optimize conditions and compositions, and synthesize substances by leveraging advanced AI and robotic technologies, thus driving an industrial revolution in the laboratory. This approach fosters serendipity by enabling unexpected discoveries that propel innovation.

※Creative AI Robotics is our group company.

Products

We have an extensive lineup of products tailored to the needs of our customers, from the liquid phase to the gas phase.

In addition to what we have introduced, we may be able to accommodate many of your requests, so please feel free to contact us for any inquiries.

Liquid Phase Technologies

We aim to solve our customers' technical challenges and achieve manufacturing through unprecedented innovation, spearheaded by our creative coating technologies.

We provide materials, equipment, processes, know-how, and intellectual property as an integrated whole.

Both-terminal and multi-terminal external electrode forming process

We have improved traditional electrode coating methods to provide comprehensive development support,including process optimization, jig and equipment design, and the selection of external electrode materials tailored to our customers' products and materials.

We offer a wide range of services, from process development to contract coating.

Our focus is on achieving optimal thin-film thickness for the top layer and ensuring thicker coatings at the corners.

Both-terminal

*Pinch or tap to enlarge.

Multi-terminal

*Pinch or tap to enlarge.

This video provides an introduction to liquid-phase technologies.

Green Sheet Coating Process

We specialize in the molding of MLCC dielectric layers (green sheets).

Our equipment ensures a clean environment in both the film unwinding and coating sections, with capabilities for in-line integration of film thickness measurement and defect inspection.

By optimizing materials, equipment, and coating processes, we provide high-quality slurry for dielectric layer production.

*Pinch or tap to enlarge.

Plating Process for Passive Components

Our equipment is designed for compactness and is capable of gold plating.

The system is composed of independent plating tanks, with each tank featuring two separate plating solution supply lines.

It is compatible with both MLCC and MLCI components, accommodating sizes from 0201 mm (008004 in) to 3225 mm (1210 in).

*Pinch or tap to enlarge.

Gas Phase Technologies

We provide next-generation vapor-phase technologies to meet the demands of the times and the environment.

By fundamentally rethinking traditional vapor-phase technologies, we contribute to technological innovation with our dual-approach solution: Low-temperature plasma-enhanced ALD (PEALD) system for semiconductors and Low-temperature plasma-enhanced ALD (PEALD) system for powders.

Low Temperature Plasma-Enhanced ALD(PEALD) Thin-Film Deposition Process for Powders

CMVA-500P

Low Temperature Plasma-Enhanced ALD(PEALD)

【Chamber size】

- □500mm

【Features】

- Low temperature plasma-enhanced ALD(PEALD) equipment in vcuum

- Powder specifications for experimental and R&D

【Application examples】

- Powders (Solid-state battery material powders, Dielectric material powders, Magnetic powders, etc.)

- Quantum dot powder

CMP-200

Low Temperature Plasma-Enhanced ALD(PEALD) Equipment for Powders

【Chamber size】

- φ200mm

【Features】

- Continuous deposition system for powders at atmospheric pressure

- For experimental and R&D

【Application examples】

- Powders (Solid-state battery material powders, Dielectric material powders, Magnetic powders, etc.)

- Quantum dot powder

CMP-400

Low Temperature Plasma-Enhanced ALD(PEALD) Equipment for Powders

【Chamber size】

- φ400mm

【Features】

- Powder deposition using swirling flow at atmospheric pressure

【Application examples】

- Powders (Solid-state battery material powders, Dielectric material powders, Magnetic powders, etc.)

- Quantum dot powder

CMVA-500P

Low Temperature Plasma-Enhanced ALD(PEALD)

【Chamber size】

- □500mm

【Features】

- Low temperature plasma-enhanced ALD(PEALD) equipment in vcuum

- Powder specifications for experimental and R&D

【Application examples】

- Powders (Solid-state battery material powders, Dielectric material powders, Magnetic powders, etc.)

- Quantum dot powder

CMP-200

Low Temperature Plasma-Enhanced ALD(PEALD) Equipment for Powders

【Chamber size】

- φ200mm

【Features】

- Continuous deposition system for powders at atmospheric pressure

- For experimental and R&D

【Application examples】

- Powders (Solid-state battery material powders, Dielectric material powders, Magnetic powders, etc.)

- Quantum dot powder

CMP-400

Low Temperature Plasma-Enhanced ALD(PEALD) Equipment for Powders

【Chamber size】

- φ400mm

【Features】

- Powder deposition using swirling flow at atmospheric pressure

【Application examples】

- Powders (Solid-state battery material powders, Dielectric material powders, Magnetic powders, etc.)

- Quantum dot powder

Low Temperature Plasma-Enhanced ALD(PEALD) Thin-Film Deposition Process(High Temperature Available as an Option)

CMVA-300

Low Temperature Plasma-Enhanced ALD(PEALD) Equipment

【Chamber size】

- □300mm

【Features】

- Thin film deposition at ultra-low temperatures (room temperature to 100℃)

Compatible with substrates and devices with low heat resistance.

- Utilizes remote plasma and long-lived OH radicals

Capable of generating highly reactive OH radicals using high-density plasma.

The long lifetime and strong oxidative power of OH radicals enable the formation of high-quality oxide coatings.

- Film uniformity and density

Enables uniform and dense film formation even within fine structures and high-aspect-ratio pores.

【Application examples】

- Capable of Deposition on High-Aspect Ratio TGV/TSV

- Capable of thin film deposition on SAW filters, solar cells, and other electronic component devices

- Ideal for R&D use (substrates up to 8-inch size)

CMVA-500

Low Temperature Plasma-Enhanced ALD(PEALD) Equipment

【Chamber size】

- □500mm

【Features】

- Thin film deposition at ultra-low temperatures (room temperature to 100℃)

Compatible with substrates and devices with low heat resistance.

- Utilizes remote plasma and long-lived OH radicals.

Capable of generating highly reactive OH radicals using high-density plasma.

The long lifetime and strong oxidative power of OH radicals enable the formation of high-quality oxide coatings.

- Film uniformity and density

Enables uniform and dense film formation even within fine structures and high-aspect-ratio pores.

【Application examples】

- A variety of powders (Solid-state battery material powders, Dielectric material powders, Magnetic powders)

- Capable of Deposition on High-Aspect Ratio TGV/TSV

- Capable of thin film deposition on SAW filters, solar cells, and other electronic component devices

CMVA-1000

Low Temperature Plasma-Enhanced ALD(PEALD) Equipment

【Chamber size】

- □1000mm

【Features】

- Thin film deposition at ultra-low temperatures (room temperature to 100℃)

Compatible with substrates and devices with low heat resistance.

- Utilizes remote plasma and long-lived OH radicals

Capable of generating highly reactive OH radicals using high-density plasma.

The long lifetime and strong oxidative power of OH radicals enable the formation of high-quality oxide coatings.

- Film uniformity and density

Enables uniform and dense film formation even within fine structures and high-aspect-ratio pores.

【Application examples】

- Capable of handling large-area substrates

- Capable of Deposition on High-Aspect Ratio TGV/TSV

- Capable of thin film deposition on SAW filters, solar cells, and other electronic component devices

- Capable of supporting from R&D to production

CMVA-300

Low Temperature Plasma-Enhanced ALD(PEALD) Equipment

【Chamber size】

- □300mm

【Features】

- Thin film deposition at ultra-low temperatures (room temperature to 100℃) Compatible with substrates and devices with low heat resistance.

- Utilizes remote plasma and long-lived OH radicals Capable of generating highly reactive OH radicals using high-density plasma.

- Film uniformity and density Enables uniform and dense film formation even within fine structures and high-aspect-ratio pores.

The long lifetime and strong oxidative power of OH radicals enable the formation of high-quality oxide coatings.

【Application examples】

- Capable of Deposition on High-Aspect Ratio TGV/TSV

- Capable of thin film deposition on SAW filters, solar cells, and other electronic component devices

- Ideal for R&D use (substrates up to 8-inch size)

CMVA-500

Low Temperature Plasma-Enhanced ALD(PEALD) Equipment

【Chamber size】

- □500mm

【Features】

- Thin film deposition at ultra-low temperatures (room temperature to 100℃) Compatible with substrates and devices with low heat resistance.

- Utilizes remote plasma and long-lived OH radicals. Capable of generating highly reactive OH radicals using high-density plasma.

- Film uniformity and density Enables uniform and dense film formation even within fine structures and high-aspect-ratio pores.

The long lifetime and strong oxidative power of OH radicals enable the formation of high-quality oxide coatings.

【Application examples】

- A variety of powders (Solid-state battery material powders, Dielectric material powders, Magnetic powders)

- Capable of Deposition on High-Aspect Ratio TGV/TSV

- Capable of thin film deposition on SAW filters, solar cells, and other electronic component devices

CMVA-1000

Low Temperature Plasma-Enhanced ALD(PEALD) Equipment

【Chamber size】

- □1000mm

【Features】

- Thin film deposition at ultra-low temperatures (room temperature to 100℃) Compatible with substrates and devices with low heat resistance.

- Utilizes remote plasma and long-lived OH radicals Capable of generating highly reactive OH radicals using high-density plasma.

- Film uniformity and density Enables uniform and dense film formation even within fine structures and high-aspect-ratio pores.

The long lifetime and strong oxidative power of OH radicals enable the formation of high-quality oxide coatings.

【Application examples】

- Capable of handling large-area substrates

- Capable of Deposition on High-Aspect Ratio TGV/TSV

- Capable of thin film deposition on SAW filters, solar cells, and other electronic component devices

- Capable of supporting from R&D to production

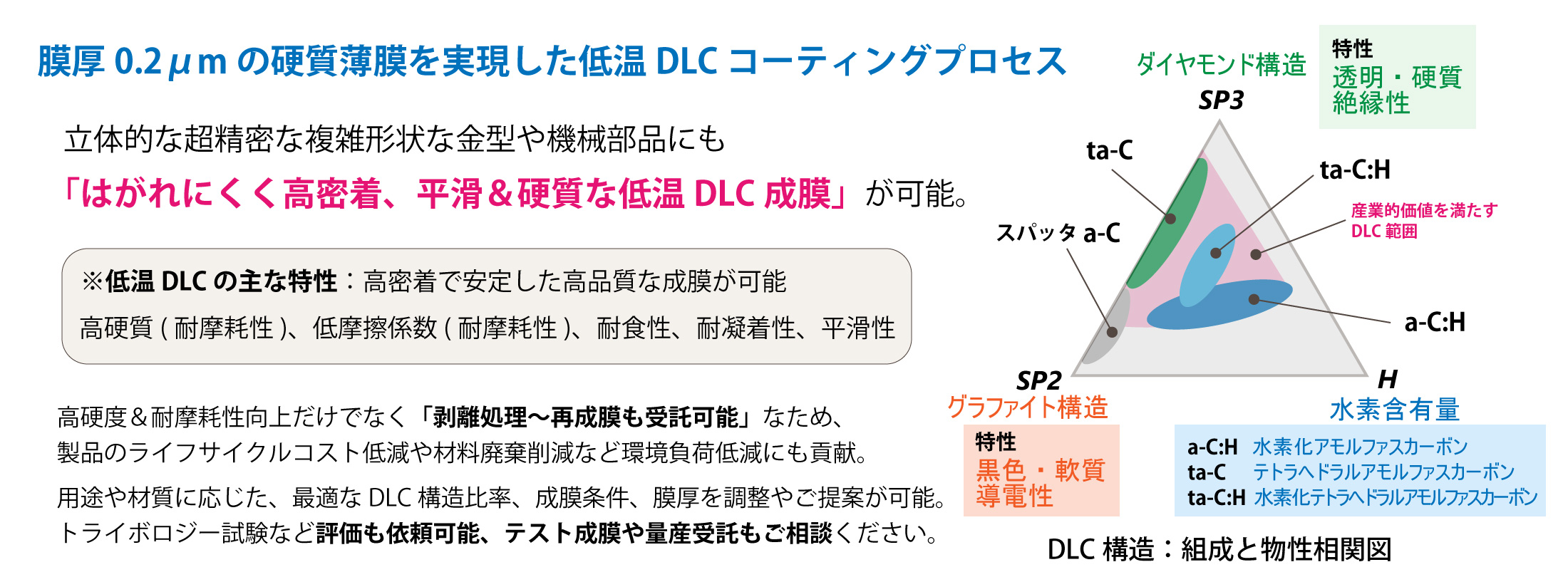

Low-Temperature Diamond-Like Carbon(DLC) Hard Coating Process

By applying high-hardness (wear resistance), low friction coefficient (wear resistance), corrosion resistance, anti-adhesion, and smooth DLC coatings, we contribute to the extended lifespan of semiconductor manufacturing equipment parts, resin molding molds, sliding components, and tooling.

Our solutions not only help customers reduce costs but also optimize maintenance operations, such as cleaning, by reducing labor hours and improving overall operational efficiency.

Low-temperature processing enables coating without compromising the base material's hardness or quality. Base materials can be metals or rubber products (such as O-rings).

*Pinch or tap to enlarge.

DLC (Diamond-Like Carbon) refers to a type of coating that possesses intermediate properties between diamond and graphite. It enables the deposition of hard thin films with excellent lubricity, offering superior wear resistance and smooth sliding performance.

By adjusting the ratio of SP3 (diamond bonds) to SP2 (graphite bonds), along with the hydrogen (H) content, and by utilizing multi-layer coatings, it is possible to create thin films with a wide range of physical properties and characteristics, offering significant industrial value.

Low-Temperature DLC

(Multi-Layer ta-C)

Hydrogen-Free DLC

Improved Adhesion Strength Compared to Conventional ta-C

【Effect】

- Enhanced Hardness & Wear Resistance

- Improved Anti-Adhesion Properties

【Film Types】

- ta-C Multi-Layer (Base Layers: Cr/Cr-N)

【Film Thickness】

- 1~2μm

【Stress】

- 50 GPa

【Friction Coefficient】

- 0.08

【Processing Temperature】

- 180℃

【Applications】

- Automotive drive components (gears, shafts, etc.)

- Precision sliding parts (bearings, mechanical components)

Low-Temperature DLC

(Multi-Layer a-C:H)

Hydrogen-Containing Cr-Based Coating

Multi-layer deposition improves load-bearing capacity

【Effect】

- Extended mold life (improved release properties & wear resistance)

- Reduced mold contamination enables longer automated operation and shorter cleaning time

【Film Types】

- CrN(multi-layer)、TiN、TiAIN(multi-layer)

【Film Thickness】

- Thin film:0.2~Thick film:8μm

【Stress】

- 20 GPa

【Friction Coefficient】

- 0.29~0.45

【Processing Temperature】

- Low:180℃, High:300℃

【Applications】

- Resin molding dies, rubber molding dies

- High-precision optical lens molding dies

- Semiconductor molding dies, precision molds, tooling

Low-Temperature DLC

(Multi-Layer CrN/TiAIN)

Hydrogen-Containing Ti-Based Coating

Multi-layer deposition improves impact resistance

【Effect】

- Improved load-bearing and impact resistance

- High adhesion prevents film delamination, extending component lifespan

【Film Types】

-

Multi-layer CrN/TiAIN

【Film Thickness】

- 3μm

【Stress】

- 25 GPa

【Friction Coefficient】

- 0.38

【Processing Temperature】

- 250℃

【Applications】

- Cold forging dies, plastic molding dies

- Punches and dies for steel processing

This video is an introduction to gas-phase technologies.